Annual Engineering Design Showcase Highlights Innovative Student Projects

Imaginative student engineers will dazzle campus colleagues and the general public when the UC Davis College of Engineering hosts its fifth annual Engineering Design Showcase from 2 to 4 p.m. Thursday, June 4, at the ARC Pavilion.

The event will feature senior projects developed by 141 teams, collectively involving 576 students. The many displays and prototypes will include ambitious endeavors in aerospace, mechanical engineering, medical and veterinary technology, electronics, chemical engineering and more.

The Showcase will be highlighted further by the presentation of the Sandia Engineering Design Award, sponsored by Sandia National Laboratories, which will recognize one team’s outstanding innovation in engineering design on a project that contributes to United States national security: either defense, natural resources or economy. Entries will be judged on the basis of a written report and a Design Showcase oral poster presentation.

Admission is free, and open to all. The official event program is available here.

This year’s Design Showcase is supported by generous donations from Boeing, Chevron, the Sandia National Laboratory and Robert Frankenberg (UC Davis ’92, UC San Francisco ’01), as well as individual contributions. More than 100 representatives from roughly 70 companies — including Aerojet, Caltrans, Chevron, DuPont, Genentech, National Instruments and Workday — will serve as judges.

“I want to especially thank the judges who will evaluate our students’ projects,” says Jean-Pierre Delplanque, associate dean for undergraduate studies. “The College of Engineering appreciates the close relationships we enjoy with our industry guests.”

“This great event allows both industry and the campus community to appreciate the hard work of our students,” agrees Alin Wakefield, an advisor in the College of Engineer’s Undergraduate Office, who is helping coordinate details. “The students, in turn, are grateful for the feedback, which further enhances their senior design experience.”

The 2015 Design Showcase’s diverse assortment of projects and inventions will include:

• A radio-frequency identification (RFID) tag reader that will track hummingbird migration patterns;

• A portable diagnostic eye-prescription instrument;

• Intelligent, autonomous vehicles and race cars;

• A scanner-controlled “Doggy Door” that prevents access by stray animals and other intruders;

• A portable water distiller;

• A safety syringe for arthritis patients;

• A lightweight, user-friendly solar pack that charges electronic devices on the go.

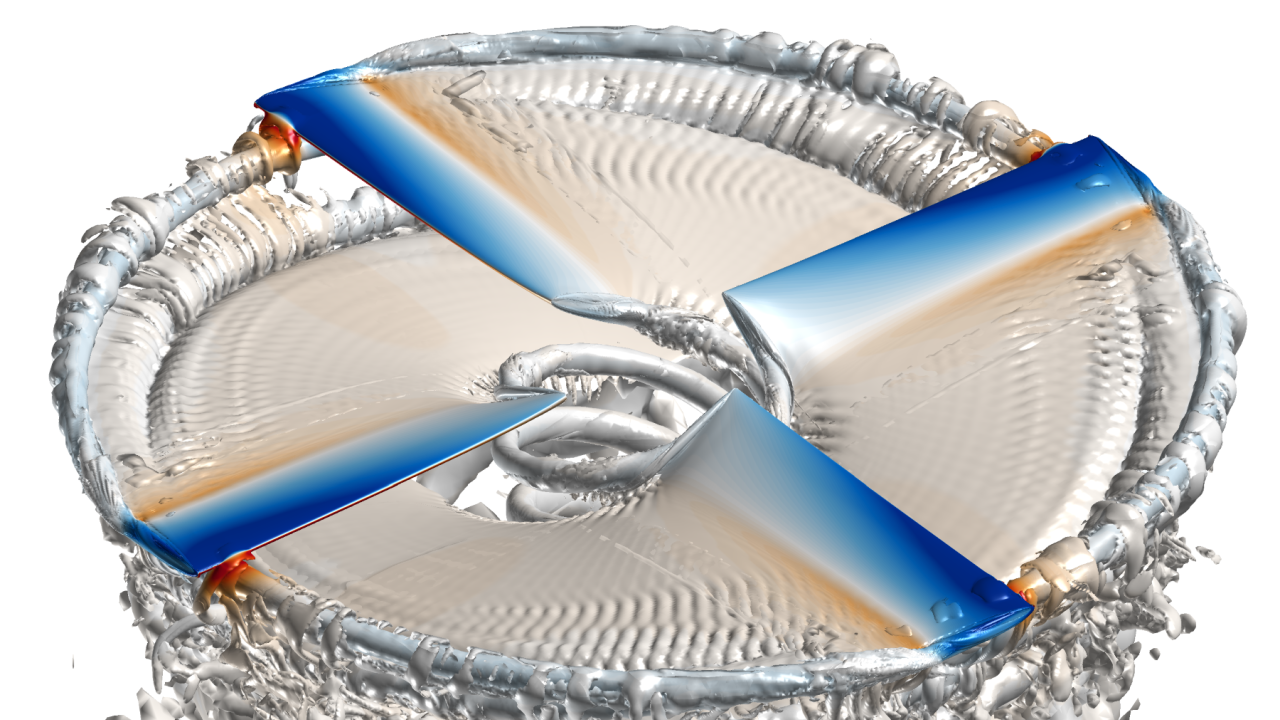

Christopher Bird and his Electrical and Computer Engineering team have developed a “detect and avoid” system that will allow unmanned aerial vehicles (UAVs) to avoid collisions autonomously.

“While flying on a pre-determined course, our quadcopter will look for obstacles,” Bird explains. “If it detects something in its flight path, the quadcopter will alter its course to avoid it. The quadcopter has a mounted camera, sending real-time video footage to a field-programmable gate array (FPGA) integrated circuit running our code. Based on what is determined from the image, along with distance signals from a LIDAR (light and radar) sensor, the FPGA sends correcting signals to the quadcopter’s flight controller.

“For the purposes of the Design Showcase, our quadcopter will fly toward and track an orange cross shape directly in its path. Once the quadcopter gets close, it’ll fly around it.”

Although the project was inspired by Amazon’s efforts to build UAV delivery drones for merchandise shipping, Bird is quick to cite the potential for more serious applications.SP15_Engineering_Design_Showcase

“Image processing and data science are highly relevant in today’s engineering community. Developing simple and effective algorithms for working with live video feeds is essential for security cameras, car-collision avoidance systems in commercial vehicles, and for military purposes such as the UAVs currently being deployed overseas.”

Elsewhere in The Pavilion, visitors will find a Comprehensive Agricultural Monitoring Sensor System (CAMSS) Robot developed by two collaborating student teams: a group led by Virginia Hartz, in the Department of Mechanical and Aerospace Engineering; and a second group led by Joshua Garrison, in the Department of Electrical and Computer Engineering.

“We wanted to make field-level agricultural analysis much easier,” Hartz explains. “We targeted strawberry fields, because it’s a big industry in California, and also because most everything still is done by hand; there’s currently a very low level of automation in every part of the process.”

The joined teams built a mobile device that resembles a large, skinny shopping cart, with an extendable “wing” that hovers over a strawberry bed while being pushed by a human handler.

The cart includes a soil probe, to monitor soil moisture, electrical conductivity and temperature; dual front-mounted cameras, for visual and infra-red imaging analysis; an environmental sensing unit, to coordinate ambient data — humidity, temperature, pressure and wind speed — with everything else; and an Android app on a mounted tablet, for GPS tracking and real-time data collection and storage for later, more detailed analysis.

“The GPS tagging is important,” Hartz adds, “as it allows the entire field to be mapped, should that be desired. The handler also can examine the generated data in real time, on both the visual and chemical levels, which allows the immediate marking of a troubled area, should one be found.”

“The visual and NDVI (normalized difference vegetation index) cameras work in tandem to detect differences in leaf color,” Garrison continues. “They highlight the ratio between the red and infrared wavelengths that are reflected from vegetation, which allows analysts to determine the amount of healthy foliage based on photosynthesis.”

The teams field-tested their CAMSS Bot on May 23, in Salinas and Watsonville strawberry fields owned by Driscoll’s and its sister company, Reiter Affiliated. “We designed our device specifically for the field geometries of those companies’ smaller strawberry beds,” Hartz notes, “which are different from most others in Southern California.”

Garrison’s team spent much of the past two academic quarters fine-tuning the complex communications issues resulting from the need to keep so many different data sets distinct, as the information travels from the various sensors to the tablet. On the mechanical engineering side, Hartz’s group faced an entirely different challenge.

“We decided to build our unit with a welded aluminum frame,” she laughs, “but none of us had welded before! We got tutorials from the staffs at the Engineering Fabrication lab and the Biological and Agricultural Engineering Shop, and one of our team members really took to it. She did an amazing job, and shaped a frame exactly the way we wanted it.”

Looking forward, both teams have high hopes for their CAMSS Bot.

“It’d be really cool,” Hartz acknowledges, “if Driscoll/Reiter decided to implement it for their own purposes.”

Ultimately, each of the Design Showcase’s 141 project teams hopes to make just that sort of industry impression.

“These students and aspiring professionals have enduring hours of drafting, modeling, prototyping, testing and analysis, to complete these projects, and all on top of an already rigorous curriculum,” Delplanque concludes. “This senior-year coursework climaxes years of precise and meticulous study, and it presents students with a collaborative opportunity to apply their skills and knowledge, in order to develop solutions to a variety of problems.”

“That said,” Bird adds, “it’s also a lot of fun!”

Photos from last year’s Design Showcase can be viewed on the College of Engineering’s Flickr pages. Additional information and a campus map are available here.