Setting the Table

College of Engineering researchers are changing the way we make — and eat — food, from burgers to boba. (Mario Rodriguez/UC Davis)

How UC Davis engineers are building toward a sustainable food future

by Jessica Heath | Engineering Progress Magazine 2024-25

With the global threat of climate change looming and a rapidly growing population estimated to reach 10 billion in the next 25 years, the need for healthy foods grown with sustainable practices is more crucial now than ever before.

Researchers in the University of California, Davis, College of Engineering are meeting this challenge head-on with research that could change the way we grow, consume and even think about food. From fungus-grown jerky to cultivated beef and sustainable systems for wine and coffee, the future of food is looking more and more promising to the palate — and nearly ready to be plated.

Whole New Ball Game

The future of food may rely on fungus and food waste, according to Professor of Biological and Agricultural Engineering Ruihong Zhang, who investigates how microbe-based foods like fungi and algae can be processed into edible products.

Zhang's team takes fungus — they have experimented with Aspergillus awamori and Aspergillus orzae — and combines it with nutrients extracted from agricultural byproducts like coffee grounds, cheese waste, almond hulls or carrot and tomato pomace (what's left over after pressing for juice or oil).

The fungus consumes the nutrients and takes on the color, flavor and nutritional value of the specific byproduct as it grows. The resulting edible balls have been processed into food items like boba, dry snacks (think: puff balls and jerky) and caviar, which Zhang and her group have dubbed "myco-foods."

Not only do these foods make use of agricultural waste, which would typically go straight into the compost bin or to a waste treatment facility, they can also be cultivated in less space than traditional agriculture. On top of that, they are packed full of protein, lipids, dietary fibers and vitamins, making them a highly nutritious and sustainable protein alternative and all-around superfood.

Swap Meat

At the UC Davis Integrative Center for Alternative Meat and Protein, or iCAMP, Professor of Chemical Engineering and Viticulture and Enology David Block leads a team of researchers working on making alternative proteins — including plant-based, fungal-based, fermentation-based and cell-based — more sustainable and accessible to the masses.

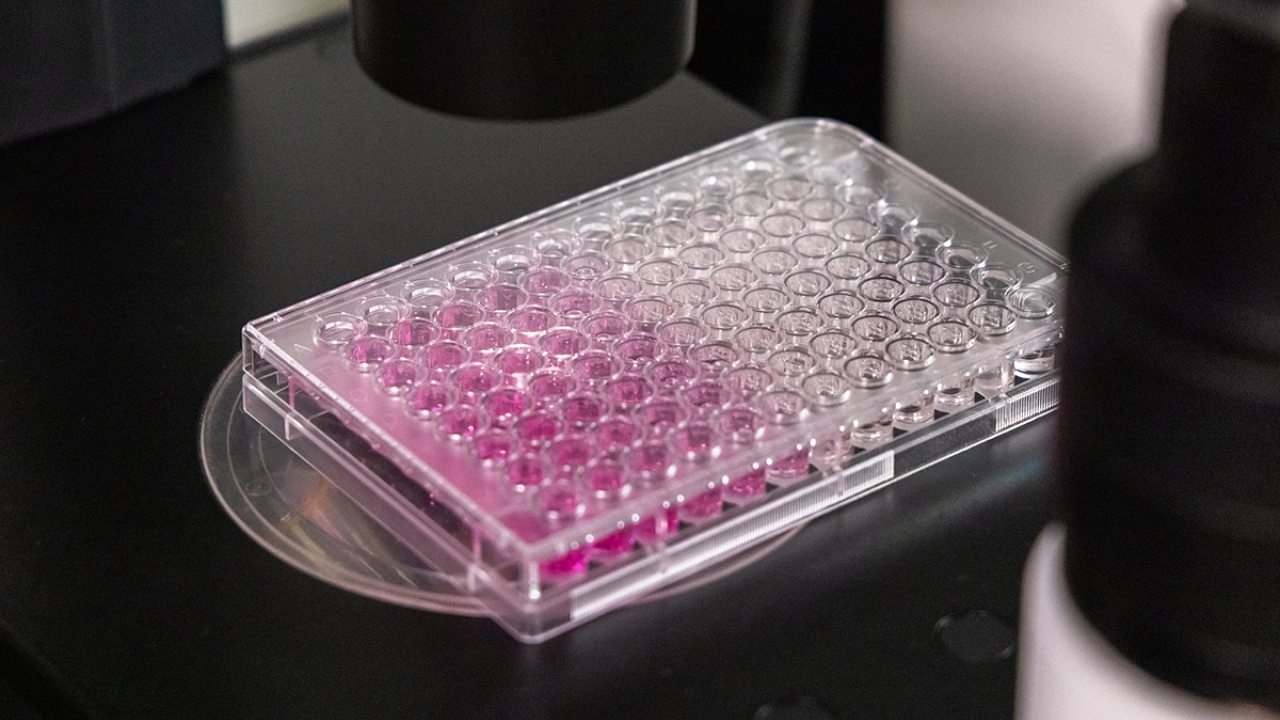

One of those researchers, chemical engineering Ph.D. student Bryan Wijaya, cultivates beef cells acquired from the UC Davis Meat Lab. Specifically, Wijaya researches media, the solution in which cultivated meat cells grow, and how to adjust its composition to make it cheaper and more sustainable.

Media comprises up to 100 components, including amino acids, sugars, vitamins and minerals — everything a cell needs to grow — and costs up to $100 per liter. Wijaya is investigating using plant extracts as a source of nitrogen instead of highly purified amino acids. He is also looking at how different combinations of plant extracts might affect the cell growth.

His goal is to get media down to under $1 per liter, which would allow companies to scale up the production of cultivated meat. Once that happens, cultivated meat could be one step closer to being next to the farm-raised, all-beef burger patties and hot dogs on grocery store shelves or on the grill at your next barbecue.

Greener Beans

As a center of excellence in the UC Davis College of Engineering, the newly opened Coffee Center is not only exposing young minds to the concepts of chemical engineering by brewing coffee; its investigators are also diving into crucial research that can make the world's second-most popular beverage (water tops it at No. 1) more sustainable.

Irwin R. Donis-González, assistant professor of cooperative extension in postharvest engineering at the Department of Biological and Agricultural Engineering, is investigating desiccants, substances that absorb or adsorb moisture (a common desiccant is the tiny packet of silica gel beads in clothing packaging), which keep green coffee beans dry and prevent molds or infestation during transportation.

Other research includes the development of noninvasive sensors to monitor moisture in stored coffee and how different roasting methods affect the physical and chemical properties of coffee beans. Graduate students are investigating the agricultural byproduct from coffee harvesting (only about 3% of coffee beans become high-quality, drinkable coffee); one innovative product is a jelly made from cascara, the coffee fruit.

This research positions the Coffee Center as a leader in creating sustainable production structures, not only for coffee but also for structures like fresh produce, says Donis-González.

"Coffee is one of the most exchanged crops in the world. Our objective is to identify opportunities, create awareness and identify steps to help producers make it more sustainable."

Redox Remix

In wine fermentation, redox potential is an oft-ignored measurement that indicates the levels and status of microorganisms and the conditions for various chemical reactions to occur. However, an unmonitored and imbalanced redox potential could have unignorable consequences.

A low redox potential, for instance, can lead to a wine tasting off or developing a sulfuric aroma like rotten eggs. To remediate this, wineries take many steps that increase labor, water and energy costs, while likely downgrading the value of the wine.

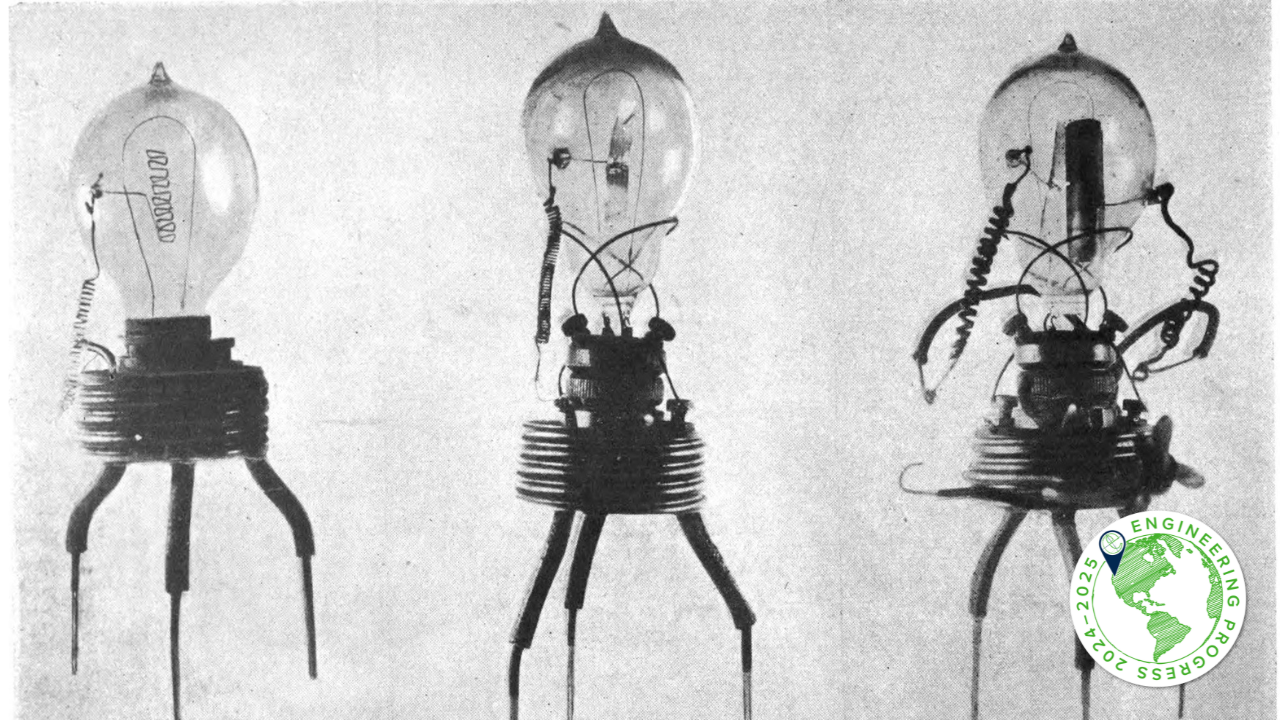

While pursuing his Ph.D. in electrical and computer engineering at UC Davis, alum James Nelson worked with Distinguished Professor Roger Boulton in chemical engineering and viticulture and enology and Distinguished Professor André Knoesen in electrical and computer engineering to develop a programmable logic controller, or an industrial computer adapted to a manufacturing process, to measure and control the redox potential during fermentation.

If the redox potential drops below a certain threshold in the fermentation tank, the controller opens a valve to let in a small amount of air; it continues to let in air or closes the valve to keep the redox potential constant. The team demonstrated their system at the UC Davis Teaching and Research Winery as well as large fermentation tanks at commercial wineries.

Controlling the redox potential can help the yeast in wine more thoroughly convert sugar to alcohol, the team's studies say, making the process more reliable and reducing the risk of spoilage or stuck fermentation and making the art of making wine a more profitable and sustainable one.

This article was featured in our 2024-2025 digital edition of Engineering Progress Magazine. Read more stories.

Featured People