Student Team Gets Eco Props for Hybrid-Electric Aircraft Design

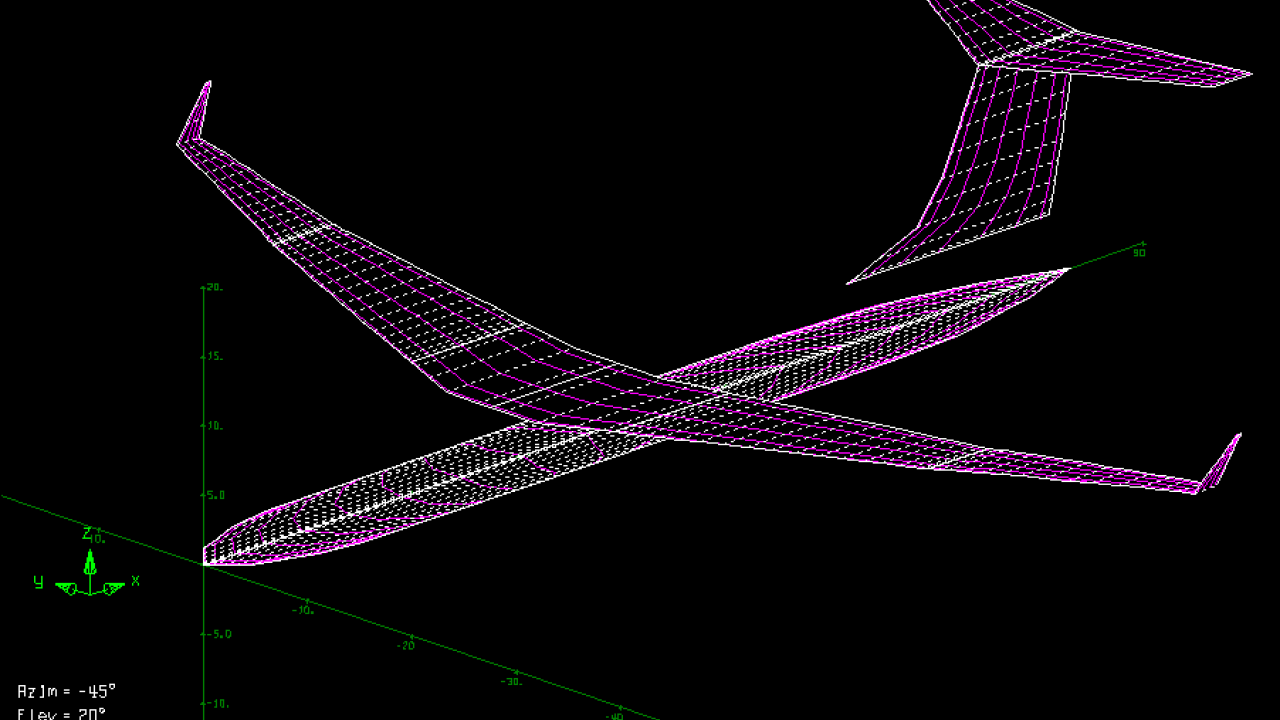

A team of mechanical and aerospace engineering students was announced as the third-place winners of the 2023 Design Competitions by the American Institute of Aeronautics and Astronautics, or AIAA, for their design of a hybrid-electric turboprop aircraft they call EcoProp.

Aerospace engineering professor Christina Harvey posed AIAA's design competition request for proposals criteria, or RFP, to her senior aircraft design class. Submissions to the competition were not required but encouraged, Harvey said.

The team, comprising Jackie The, Bryan Tiang, Ethan Brown, Loe Yer Yang and Ryan Chen, was one of three teams in Harvey's class that submitted their final designs to the competition.

The RFP asked student teams to conceptualize a hybrid-electric, 50-seat turboprop aircraft with at least 20% better fuel emissions and efficiency than current technology, like the De Havilland Canada Dash 8 Q400, but still costs about the same to build. Some more advanced criteria included autonomous operation capability and a breakdown of the battery pack system, which Harvey pointed out aren't covered in her class.

"This team was very detail-oriented and willing to learn," she said. "If I said, 'Hey, I didn't teach you this,' they would go find it and figure it out. They were very particular about making sure they hit their targets and that they compared to existing designs first to take theirs to the next level."

The, Tiang, Brown, Yang and Chen said the most challenging aspect of the project was the assumptions they had to make regarding the hybrid-electric element. The wingspan of the aircraft, for example, kept changing due to the addition of different constraint calculations, like the electric battery weight and the maximum wingspan allowed at an airport. But the team couldn't look at conventional aircraft for specs.

"Designing a conventional aircraft, we have a wealth of information to go off, but because this project is an electric hybrid, not many people have done it," said Tiang. "A lot of the technology is still in development. There are a lot of assumptions and judgment calls we had to make by just looking at the data."

Harvey also brought in industry expert Benjamin Brelje, the multidisciplinary optimization staff engineer at Joby Aviation (which, coincidentally, was founded by alum JoeBen Bevirt '95), to evaluate the teams' designs. The team said this experience made the whole process — from conjuring an idea to fully realizing a buildable aircraft – seem more tangible than at the beginning of the class.

"Doing a review with someone from the industry really helps put it into perspective of what they're focused on," said Brown. "The experience of starting off knowing basically nothing about aircraft design, and through the course of about two quarters, you get an idea of how it's done in a real sense, that whole process puts aircraft design into something we can actually comprehend now."

The AIAA Design Competitions are held annually and give students the chance to "perform theoretical work and gain real-world insight into the design process" of an aircraft, engine, or space vehicle.

"Design competitions help students solve real-life problems and prepare them to make an impact in the aerospace community. These young people receive valuable feedback from technical experts who serve as volunteers on AIAA technical committees," said AIAA Executive Director Dan Dumbacher. "Everyone who participates in these competitions is shaping the future of aerospace."