Big Data Comes to Dinner

From Seed to Plate, Artificial Intelligence Is Transforming How and What We Eat

Artificial intelligence is already changing how people work, communicate online, create art and manage businesses. Now the technology is being used in every aspect of our food systems.

AI holds the promise of making agriculture more efficient and sustainable, yielding healthier food with less impact on the planet, according to Ilias Tagkopoulos, director of the Artificial Intelligence Institute for Next Generation Food Systems, or AIFS, at UC Davis.

Take the humble tomato, for example. In California, where some 13 tons of the fruit were harvested last year, researchers from UC Davis and other institutions are using AI to reduce loss of tomatoes as they are trucked from field to cannery. AI can help us develop new tomato varieties adaptable to a changing climate and screen fruit for quality in the processing plant.

AI algorithms can make predictions and recommendations based on very large amounts of data. Pacific Coast Producers cannery in Woodland, California, uses data every step of the way including sorting the fruit — and AI can lead to even more efficiency, said Dan Vincent, who retired last year after 19 years as cannery CEO.

“We’re already using ‘I,’ in AI. The ‘I’ are people, and they do a very good job, but they’re overwhelmed with data. So can AI help those people do their jobs better?” Vincent said.

Decisions from big data

AI is essentially a set of tools that creates decisions from data, said Tagkopoulos, who is also a professor in the UC Davis Department of Computer Science and Genome Center. Those tools can support human decision-making as our systems become more complex.

“The more complex the system becomes, the more the analysis of data and finding the best point of operation becomes difficult. And the food system is really, really complex,” he said.

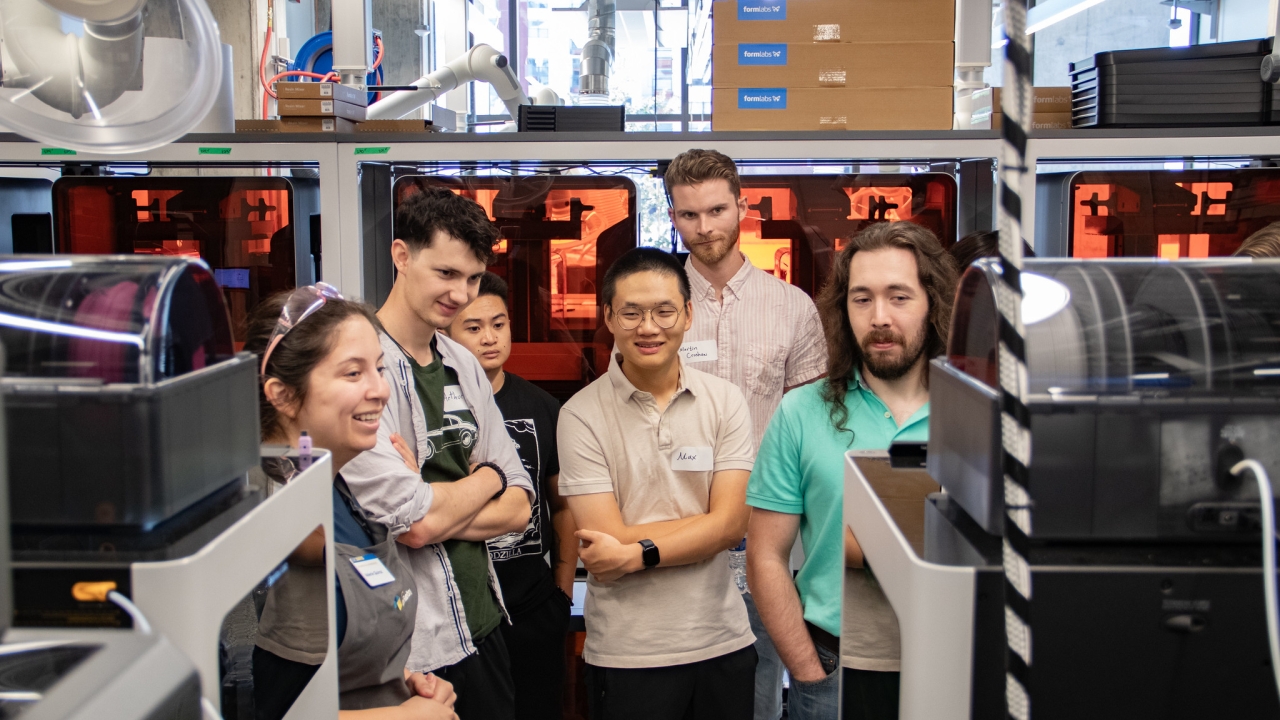

The seed for the AIFS began with a White House initiative on artificial intelligence in 2019. In 2020 the National Science Foundation and partner agencies issued a call for proposals for institutes working on AI in various fields, including food systems. The AIFS, led by UC Davis and including UC Berkeley, the University of Illinois Urbana-Champaign, Cornell University and the University of California’s Division of Agriculture and Natural Resources, was established that year with a grant from the U.S. Department of Agriculture’s National Institute of Food and Agriculture.

In its first three years, the institute has funded research projects on AI technology across the food system, from cheaper sensors for agricultural production to digital simulators to manage indoor farming and technology to predict the nutritional content of food.

As large-scale data collection and AI become routine at different steps in the food supply chain, those steps can themselves be integrated by AI.

“Where the opportunity lies is in integration — connecting the dots throughout the supply chain,” Tagkopoulos said.

For example, information gathered by AI about crops growing in a field can be integrated with the AI for plant breeding. That integration up and down the supply chain is a key goal for the AIFS as it enters its fourth year, Tagkopoulos said.

Making the seeds: AI in plant breeding

One of the original innovations in agriculture was to select and breed plants that make good crops. Today, plant breeders and geneticists continue to push for plants that are tastier, hardier, and more drought or pest resistant. With the rise of modern genetics, breeders can use genetic information to select plants to cross with each other and create new varieties.

“The genetics helps inform the breeding,” said Christine Diepenbrock, assistant professor of plant sciences at UC Davis. “We can find different regions of the genome that are favorable for traits of interest, then cross the best lines together and make sure we get all those different favorable regions.”

The more information breeders have about the plants, the more quickly they can create the best crosses. Artificial intelligence can support those decisions, Diepenbrock said.

“So we can get gains more quickly if we can accurately predict how the next generation is going to perform, or how a given crop variety might perform in a new environment where we haven’t tested it before,” she said.

Artificial intelligence is particularly useful for finding complex, nonlinear relationships, Diepenbrock said. For example, recent work by one of Diepenbrock’s students studied ways to use DNA sequences to predict carotenoid (provitamin A) concentrations in maize.

Plant breeders often must consider several traits at the same time. Your tomato may be drought tolerant and pest resistant, but you also want it to be nutritious and flavorful. AI can be useful in understanding and taking advantage of the complex relationships between these traits, Diepenbrock said. Combined with DNA sequence information, AI can speed up the breeding cycle and bring new varieties forward more quickly.

In the fields: bolstering ag-tech

Sown into fields, farmers must nurture their plants into a crop. That presents many opportunities for AI to increase yields and quality while saving resources, said Mason Earles, assistant professor in the Department of Viticulture and Enology and Department of Biological and Agricultural Engineering, who leads the agricultural production cluster of the AIFS.

The ag-tech industry is already taking notice. Precision agriculture uses agricultural technology, including AI, to monitor and cater to the needs of crops in real-time. Precision agriculture can help farmers minimize waste, use resources efficiently and support sustainable farming practices by providing just the right amount of water, fertilizers and protection against pests to the plants that need it, exactly when they need it.

“There are a number of businesses all the way from startups up through large scale producers and machine manufacturers who are doing this sort of thing right now,” Earles said.

Major manufacturers like John Deere already produce “see and spray” technology, which can automatically and selectively deliver fertilizer or pesticides where most needed, for row crops like wheat and soybeans. A challenge for California agriculture is that speciality crops — fruits, nuts and vegetables — vary a lot in their growing conditions and requirements.

“Building tools around AI that work in almond is very different from grape, is very different from strawberry; it’s different from lettuce,” Earles said.

Using data is not new in agriculture, Earles noted. But now AI could take different kinds of data — images of plants from video cameras on tractors; water and fertilizer inputs; soil, weather and other environmental conditions — and combine it to produce forecasts to support farmers’ knowledge and experience.

“It’s sort of giving them a superhuman suit, to be able to go out and do better the things they’re already doing,” Earles said.

Precision agriculture technology developed in Earles’ lab at UC Davis is being commercialized by Scout, a startup company based in Napa County and Davis. Instead of a farmer walking through their vineyard and inspecting vines in person, Scout’s technology uses AI to analyze thousands of images of grapevines collected at ground level and provides insights.

Onto the truck: AI minimizing food loss

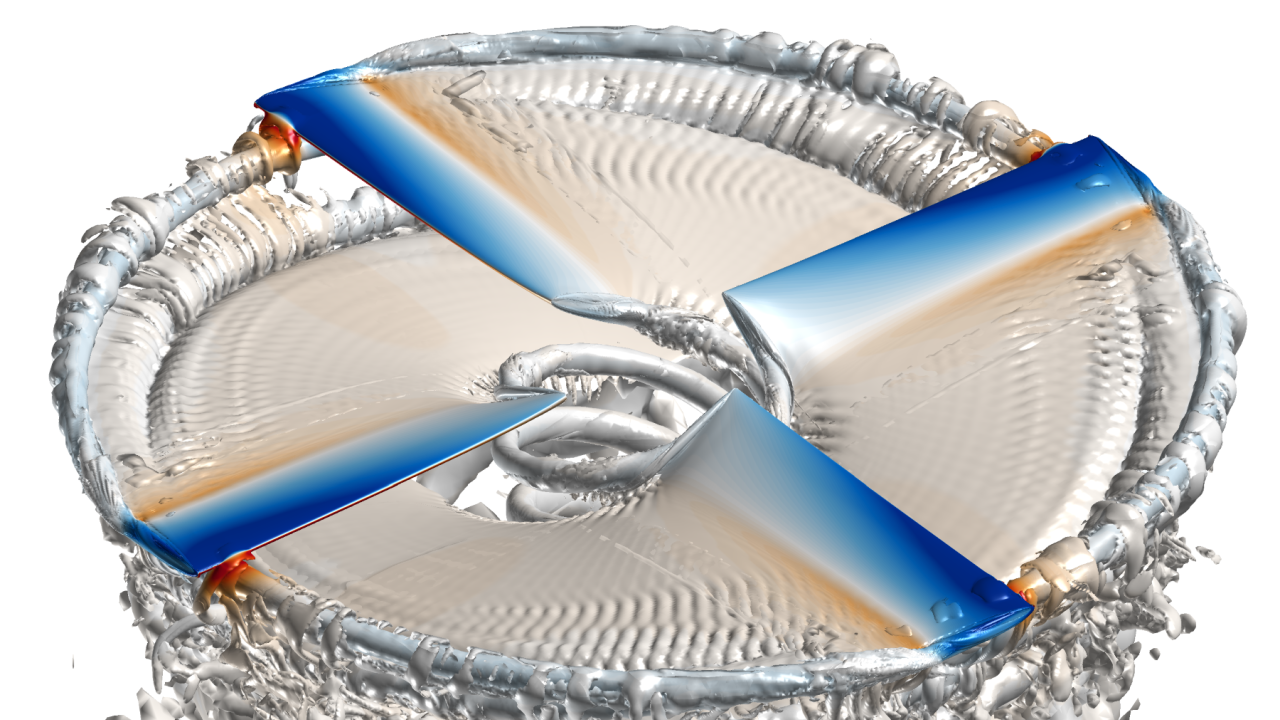

Early summer in the fields around UC Davis, mechanical harvesters are separating fruit from tomato plants and loading it into open trucks — called gondolas — for transport to nearby canneries. Along the way, some of the tomatoes may get split or squashed and leak fluid, known as serum. Others may be moldy or unripe. All of these are losses for the producers.

Christopher Simmons, professor and chair of the Department of Food Science and Technology at UC Davis, has used AI to study the factors that give rise to loss of quality before tomatoes get to the cannery gate.

“We wanted to predict when these losses might occur, in order to design interventions that would maintain quality and preserve tomatoes,” he said. While the number of tomatoes rejected is small compared to the size of the harvest, it’s still a concern for processors, he said.

“It’s also a loss of all the resources that were used to produce those tomatoes — all the water, the energy, the fertilizer, other inputs are lost each time a single fruit is rejected.”

Big data on tomatoes

Simmons and a multidisciplinary team at UC Davis and UC Berkeley were able to draw on years of data collected by the Processing Tomato Advisory Board on every load of tomatoes arriving at a processing plant, including variety, season, where it was grown and quality measures.

Their first challenge was to get all this data — from archives, from documents, on different scales in space and time — aligned and in a format that could be used to train an algorithm.

“The quality of the algorithm is going to reflect the quality of the data used to train it,” Simmons said.

Over the course of the project, which was supported for two years by the AIFS, the model did identify some weak but significant predictors for likelihood of mold, specifically the time of season and the acidity of the tomatoes.

New sources of data could make the model more robust. Engineers Ana Arias and James Evans at UC Berkeley, also collaborators at AIFS, have developed a sensor array that could be mounted in the gondola to measure the forces on tomatoes as they are trucked to the processing plant, as well as the level of serum leaking from damaged tomatoes.

The data so far are preliminary, Simmons said, but if these kinds of sensors were in use throughout the industry, they could generate a layer of data that would strengthen predictions.

Into the can: AI transforming the cannery

Once tomatoes enter a plant like Pacific Coast Producers’ cannery, they enter a high-tech, highly automated environment. Former CEO Vincent said he has seen a lot of change at the company since he started working there in 1983.

“At the time it was very labor intense — many people working there, pretty much hand sorting, hand stacking of cans,” said Vincent. Today, the Woodland plant is highly automated with a small, highly skilled workforce.

Pacific Coast Producers is a cooperative owned by about 170 farmers. It operates several plants in California and Oregon, supplying store-brand canned fruit and tomatoes to major retailers across the U.S.

For Vincent, AI is another tool to help processors deliver products to their customers.

“Whether it’s tomatoes, diced tomato, tomato paste, or sliced peaches, pear halves or maraschino cherries, our job is to take that raw product and get it to the state the customer wants, at the lowest possible cost, at the highest quality,” he said. To that end, the industry already uses high-speed color sorters that use cameras and a rudimentary AI to accept or reject fruit as it passes by.

Pacific Coast Producers sells about 200 different product types (SKUs, or “stock keeping units” in industry parlance) to most retailers and food service distributors in the U.S. Those products leave the cannery unlabeled, or “bright,” and go to the company’s distribution center in Lodi, California, for labeling.

There, staff have to figure out the most efficient way to label all the different products for all the different customers while minimizing the number of times they have to change over the equipment.

“For a company like ours, it’s 14,000 data intersections, so 14,000 theoretically unique items you have to manage,” Vincent said. “So that’s where I see a real opportunity for AI, because we have very good data; it’s just a lot of data.”

Plates and stomachs: AI in nutrition and diet

Imagine having an expert dietitian at your side who could tell you what’s in your meal and what effect it will have on your body. That’s the potential of an AIFS project led by Danielle Lemay, a research scientist at the USDA’s Western Human Nutrition Center in Davis and an adjunct professor at the UC Davis Department of Nutrition.

“[Our] main project with AIFS is trying to predict health from food photos,” Lemay said.

Nutritionists use food diaries, questionnaires and peoples’ recollection to try to track what people eat. These methods are tedious and not very accurate.

“Wouldn’t it be great if we could just use our phones to capture what we’re eating in order to better inform dietary assessment?” Lemay said.

Take a picture of your meal, and an AI could give you a complete breakdown of the ingredients for nutritionists to study.

Alongside the photographic food diary, Lemay is collaborating with Tagkopoulos on an AI-based dietary recommendation system that can start with an image of a food and come up with a detailed list of ingredients and micronutrients, its health effects and interactions. Lemay and Tagkopoulos are working with Hamed Pirsiavash, associate professor in the Department of Computer Science, on algorithms that can generate information based on an image.

“There’s this whole world of thousands of molecules in each food that we’re starting to map with analytical chemistry,” Lemay said. “If we were able to map foods to databases that tell us about these thousands of molecules, then that opens up the opportunity to understand more about how the molecules and what we eat impact things like your gut microbiome or other aspects of health.”

Human nutrition is staggeringly complex. You have to consider all the molecules that make up the ingredients of your meal, most of them still unknown; all the variation between individuals, in age, weight and genetics; and the millions of microbes that live in our gut and help us digest different foods.

Finding a path through the millions of possible interactions between all these variables is very difficult for human brains, but it’s the kind of big data problem that AI and machine learning can do easily.

From seeds to fields to stomachs, AI technology is already having an impact on our food supply.

“Whether we realize it or not, AI is becoming interwoven into many of the tools, software hardware that we rely on. I think we’re going to see the same thing in the food system,” Simmons said.