Where Art Meets Alloy

New bladesmithing club blends materials science with craftsmanship

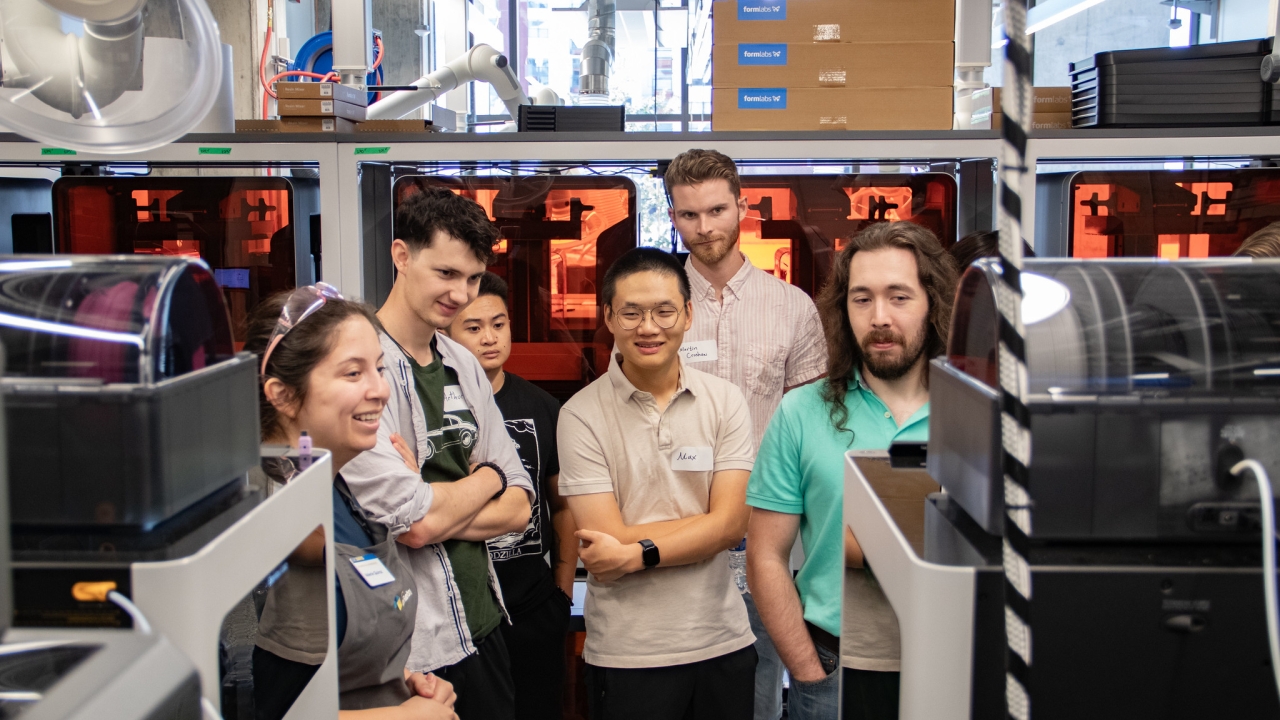

On any given day at the University of California, Davis, you will find students in a Bainer Hall garage outfitting an electric car for the future, or in the Diane Bryant Engineering Student Design Center 3D printing a prototype of a portable bioreactor.

One of those students, third-year materials science and engineering major Aaron Diamond, can often be found at the Craft Center working on his passion project: bladesmithing, or making knives, blades and swords.

Now, after years of honing his craft, Diamond is sharing his knowledge with other students at UC Davis by starting the first-ever UC Davis Bladesmithing Team, learning about how materials shape the tools we use in the process.

Education Forged by Doing

Diamond took an interest in bladesmithing in high school because it allowed him to use his hands to make a physical product. After watching a couple of YouTube videos, he began making small knives with tools he already had at home.

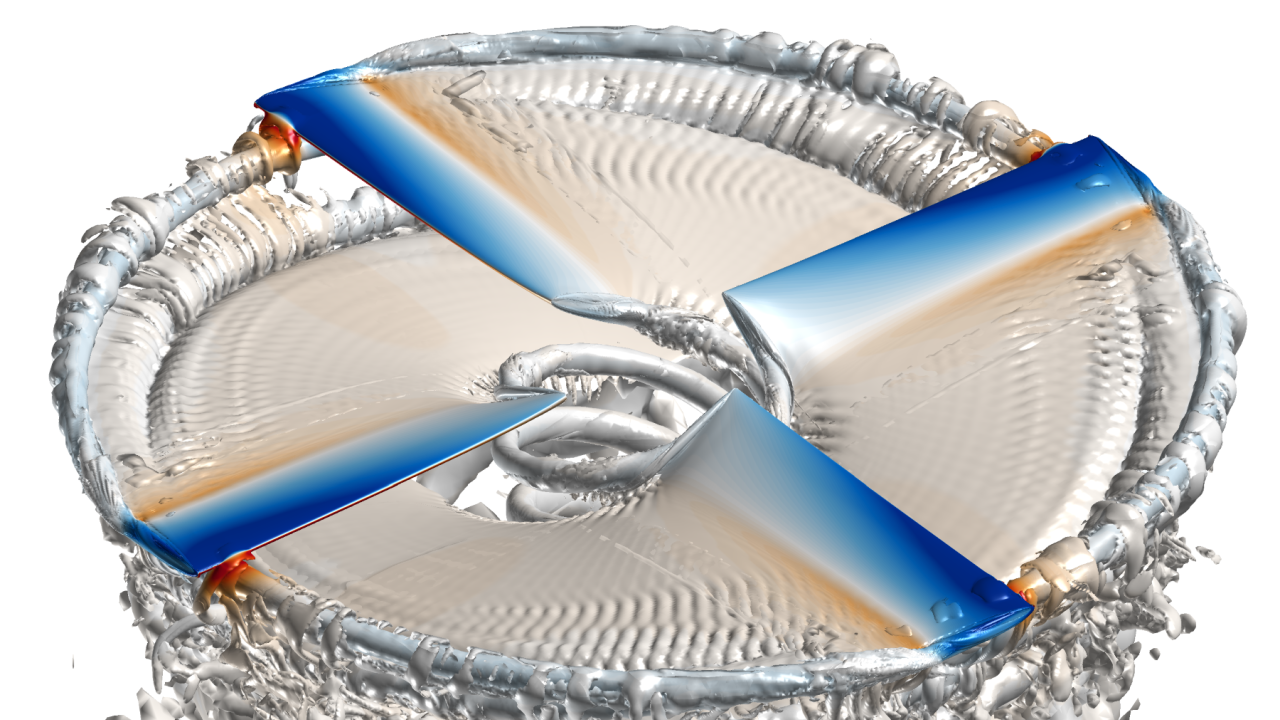

With a combination of acquired scrap metal and specialty materials in his backyard and garage, he was able to teach himself about materials science and fundamental bladesmithing techniques. His favorite step, called quenching, inspired him to choose a major in materials science and engineering.

“A key step of the process is heating the steel to around 1500 degrees Fahrenheit and then plunging it in oil, and that changes the internal structure of the steel on the atomic level,” said Diamond, describing quenching. “I thought that process was super cool because it made the properties of the steel change completely.”

Now, Diamond is using his interests to further his skill set in materials science and share his knowledge of bladesmithing with other students who are interested via the UC Davis Bladesmithing Team. He started the bladesmithing club following an email from Amir Saeidi, an assistant professor of teaching in materials science and engineering, about a national competition for bladesmithing that happens at the Minerals, Metals & Materials Society annual conference. The UC Davis team plans to compete at the 2026 meeting.

“It hadn’t crossed my mind that I could create a club,” said Diamond. “Then Saeidi offered support, some initial funding, and I was like, ‘If I have a faculty member backing me, I can actually do this.’ And so far, there's been about 25 people who have joined.”

Blades of Glory

Since fall 2024, Diamond has been working with campus organizations to ensure safety and tool access is available to everyone in the club. They have been granted access to the Craft Center — a space to take classes to improve as a creator, work in studios and show off art from students — to practice bladesmithing.

General meetings for members are held weekly on Mondays from 5-6 p.m. in a basement room of Kemper Hall. Club members meet throughout the week at the Craft Center in small groups to use machines like the forge and belt grinder.

“We're doing a mini knife project right now where members are putting handles on blades that have already been made,” said Diamond. “That gives a good introduction to the tools that are used, the thinking involved, the safety equipment needed and the workflow life, making us do a lot of sanding and grinding.”

Once these blades are finished, Diamond wants to get the members to make a couple of blades themselves, which they hope to sell and use for fundraising. The main knives that will be created are camping knives and kitchen knives.

Diamond hopes to develop his own skills and learn more about materials science through this club, learning other methods of bladesmithing and blacksmithing such as making Damascus steel. This can be created by the layering of different steel and then etched to show a pattern.

“It doesn't have any performance benefits. It's just an aesthetic thing, but it's pretty challenging, and you do need a good forge and anvil setup, which I previously haven't had,” said Diamond. “With some of the equipment in the materials science labs, we will be able to characterize the steel well to see if those different layers have stuck together.”

Once they gain some experience with Damascus, the club members may be able to try out infrequently used alloys and other materials using the powerful microscopes in the materials science and engineering labs they now have access to. This will allow Diamond to innovate with the steel they use to make their blades.

“Making knives teaches so many skills — it teaches woodworking, metalworking, material science, engineering and artistic design,” Diamond said.

Welcome to the Club

Since starting at UC Davis, Diamond has joined a handful of clubs. He is currently the assistant project manager for Concrete Canoe, a club that is challenged with the task of creating a functional canoe out of concrete.

Diamond says participating in clubs has been instrumental in his education. Not only has he gained experience with club organization and logistics, which have been helpful skills for creating the bladesmithing club, but also important foundational skills to build on for his future career.

“I've gotten the opportunity to make a lot of mistakes in these clubs where the consequences aren't severe, and when I'm working on future projects, the consequences of those mistakes are going to be much more dire and expensive,” said Diamond. “It's a good way to learn.”

Though he started the UC Davis Bladesmithing Team mostly as a way to find a space for bladesmithing and to have access to more resources, Diamond is excited to share his passion with others who are interested in the scientific craft.

“The process of starting a club has been both stressful and exciting,” said Diamond. “There's a lot of coordinating with different people in the department and organizing, which can be difficult, but I'm excited to get things going.”