Engineers Invent Machine to Shake Up UC Davis’ COVID-19 Testing

UC Davis engineers have invented shaking and inversion machines that are a critical part of the UC Davis Genome Center’s award-winning asymptomatic COVID-19 testing. These machines, designed and built by biological and agricultural engineering (BAE) development engineer Dennis Sadowski, professor Stavros Vougioukas and postdoctoral researcher Zhenghao Fei in just six weeks, help treat saliva samples so they can be tested for the virus.

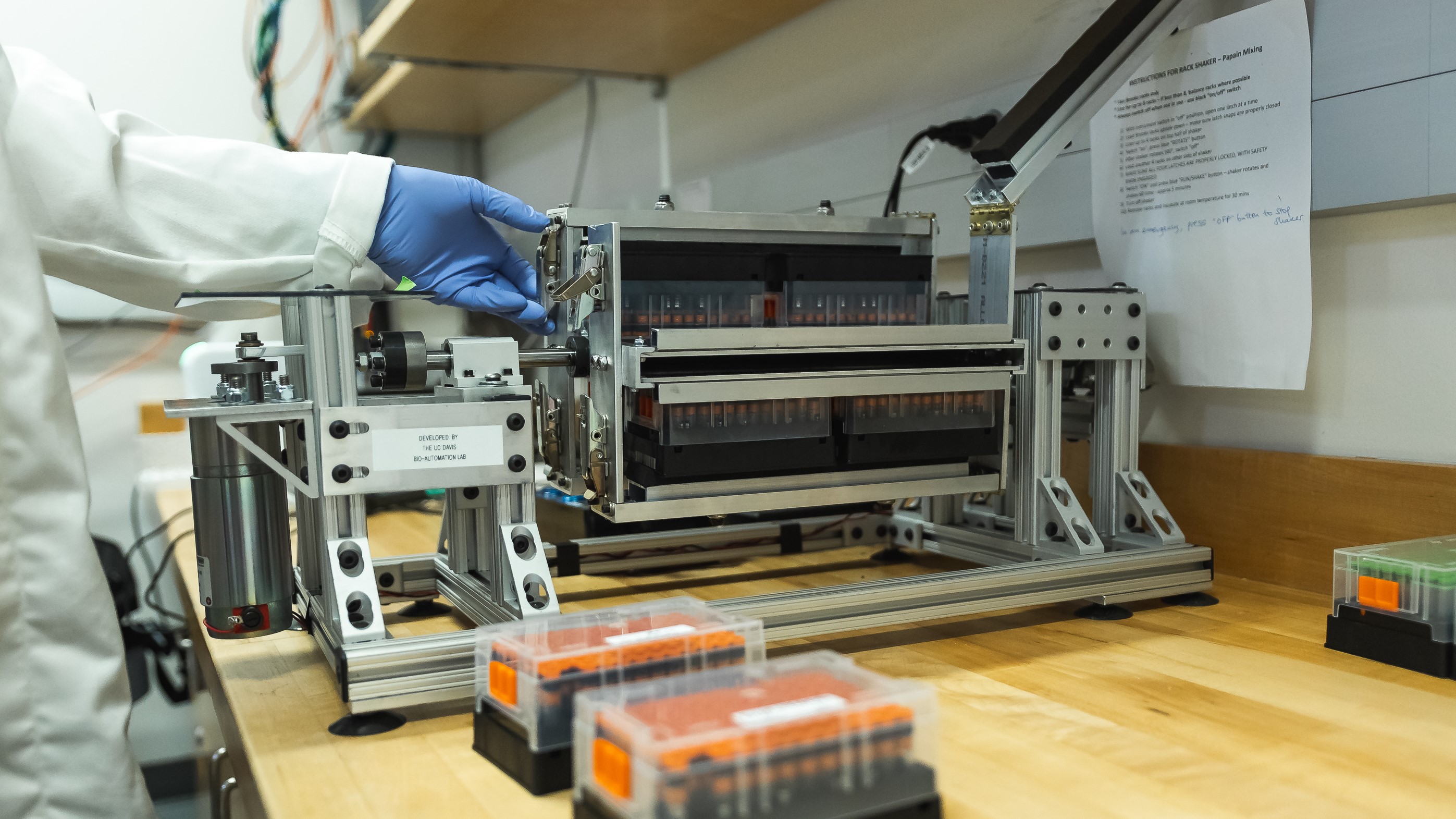

One of the most important steps in the Genome Center’s testing process is mixing the viscous saliva samples with papain protease, an enzyme that makes these samples less sticky so they can be used in a pipette later in the process. To mix the enzyme evenly into the viscous and stringy saliva, the samples need to be vigorously shaken and inverted.

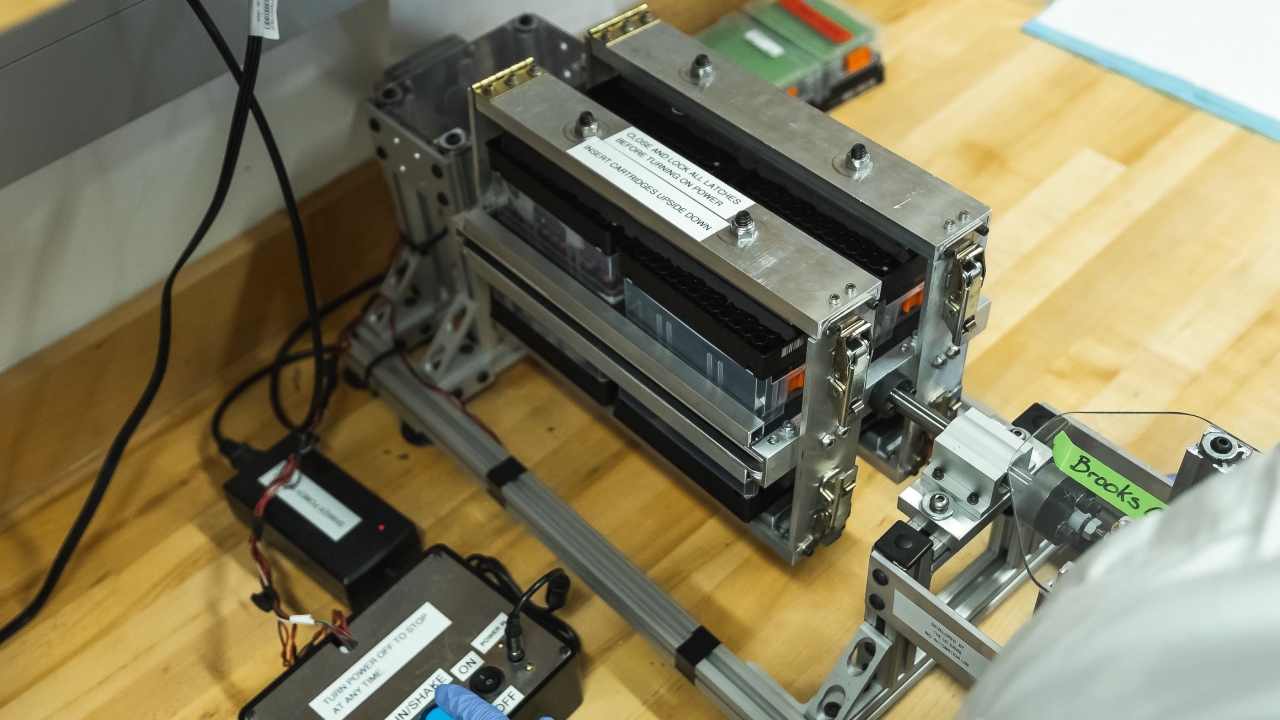

The shakers automate this step and can process 768 saliva samples at a time across eight cartridges. They shake samples for three seconds, rotate them 180 degrees and shake them again, repeating this process 60 times—about six minutes in total. Since being deployed in February 2021, the two shakers have handled an average of 3,000 to 4,000 samples per day.

“After this process, the samples are perfectly pipettable without any problem,” said Lutz Froenicke, the Genome Center’s DNA Tech Core manager who oversees the COVID testing lab. “It’s what enables the rest of the testing.”

Meeting a Rapid Need

For the first several months, shaking and inverting was done by hand. As the pandemic—and testing—peaked in late 2020, the Genome Center realized they needed a way to standardize the procedure and reduce strain on workers.

“If you have one critical step in the lab like this, you want to do it with a machine,” said Froenicke. “You can do it easily by hand, but you also want to have each rack treated reliably.”

The center reached out to Vougioukas, a robotics expert in the College of Engineering, about building a machine to execute this process. Vougioukas enlisted Sadowski and the two spent their winter break working on a design. Though shaking devices for lab samples are nothing new, this one was unique because it had to incorporate inversions.

“I’d never built anything quite like this before,” said Sadowski. “That flipping action was crucial, and it took some ingenuity to come up with a way of allowing the shaker to quickly and freely move back and forth and rotate at the same time.”

To make sure the inversions were reliable and repeatable, they brought in Fei, who designed the machine’s electronics and programmed a routine so the machine would perform its actions a set number of times.

After a little more than a month, the first prototype was built. Three days later, Froenicke and his colleague Vanessa Rashbrook visited the BAE shop to see the design and conduct tests. By early February, the completed shaker was delivered to the Genome Center and incorporated into their standard operating procedure.

“It was a lot of long hours, but with people dying, we needed to get the testing ramped up big time,” said Sadowski.

Making a Difference

Though Froenicke and Rashbrook’s team was initially reluctant about introducing a machine into their procedure, they quickly warmed up to it.

“[Shaking and inverting] creates a lot of repetitive strain, so the shakers saved people’s arms and standardized everything nicely,” said Rashbrook.

The shaker was so successful that the Genome Center requested a second machine, which was built and deployed in March. Since then, the two have shaken every sample that’s come to the lab from both UC Davis campuses and the City of Davis.

“The shakers make it so much easier to process large numbers and make everything uniform,” said Sherri Wykoff-Clary, who works in the lab. “If a sample has an issue, we know it’s not because the papain somehow didn’t get mixed in.”

Sadowski, Vougioukas and Fei have also worked to patent their idea. They say the shaker might be useful in any situation where viscous liquids in small vials need to be mixed. The team secured a provisional patent in June, the first step toward a full patent, and they are working with the Office of Research to market the technology to industry this summer.

The team is proud that they’ve been able to play a role in helping keep the community safe and look forward to making this technology more widely available.