'This Project is Mushrooming'

Building Compostable Wind Turbine Blades from Bamboo and Mycelium

It is the year 2035. In a world facing climate catastrophe, the human enterprise is powered by fields of wind farms, with turbine blades made from fast-growing grasses and the roots of a million-year-old fungus.

It may sound like a scene from a climate-fiction movie, but polymer composites expert Valeria La Saponara, a professor in the Department of Mechanical and Aerospace Engineering, has a vision to develop compostable, ecologically sound wind turbine blades from bamboo and mycelium, the fungal root-like system that bears mushrooms. With seed funding from the College of Engineering's Next Level strategic research vision and a grant from UC Davis Sustainability’s The Green Initiative Fund (TGIF) behind the initial phase of research, La Saponara, co-PI Michele Barbato in the Department of Civil and Environmental Engineering, and a diverse team of students and researchers in the Advanced Composites Research, Engineering and Science (ACRES) laboratory are developing a prototype to test on campus this winter.

The Trouble with Wind

Wind is one of the fastest growing sources of renewable energy in California and around the globe. It is a key part of California’s path to carbon neutrality by 2045. China, which accounts for more than half of global wind power, is planning to build a wind farm that could power 13 million homes by 2025 as they work toward their 2060 net-zero goal.

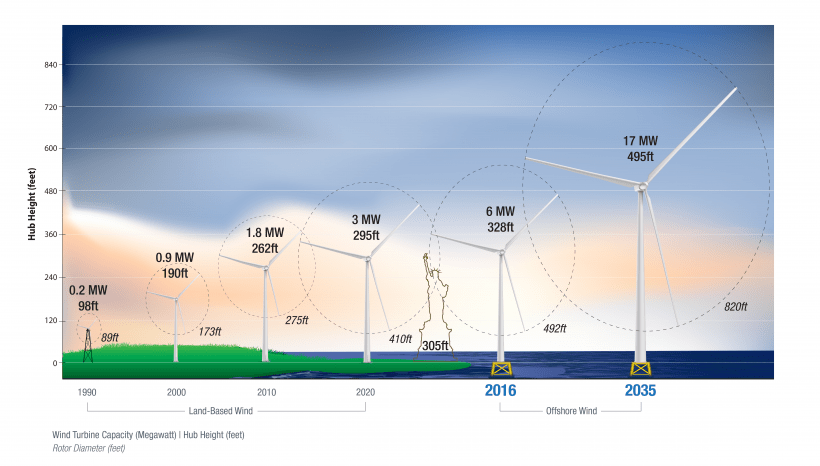

The expanding role of wind is largely good news. But as this key source of renewable energy grows, an environmentally sound solution is needed for the exponentially growing number of wind blades bound for landfills. Wind turbine blades are huge: the average rotor diameter in the U.S. in 2021 was 418 feet, so a single blade is almost as big as a Boeing 747’s wingspan. Designed to be resilient against heavy winds and weather conditions, the blades have a lifespan of about 20 years before they are retired or replaced. Most are constructed using a composite structure of fiberglass/epoxy built on top of balsa wood, which adds stability and flexibility. Recycling options are very limited, costly and incur the additional carbon footprint impacts of transportation.

Most wind turbine blades end up in landfills. In the U.S. alone, more than two million tons of decommissioned blades are projected to be sent to landfills by 2050 according to a recent study; globally, the mass of all the blades expected to be retired by 2050 may be as high as 43 million metric tons. The use of balsa wood is an additional, devastating ecological impact. Rapid growth in the wind power industry has caused overlogging in the Ecuadorean Amazon rain forest, resulting in unchecked deforestation and societal harm to indigenous communities in the region. Some manufacturers have been switching to PET plastics, adding to the millions of tons of PET waste in the environment.

Compostable Blades

For La Saponara, wind blade pollution is an urgent problem.

“We want to have clean energy, but clean energy cannot pollute the environment, and it can’t cause deforestation,” La Saponara said. “If we’re doing clean energy, it’s not to deforest the Amazon rainforest. We want to be good citizens for everybody.”

La Saponara envisions a compostable wind turbine blade built with woven bamboo, mycelium and biomass from the agricultural waste from California’s Central Valley in place of fiberglass and balsa wood. She first began working with mycelium in 2019, when she sought an alternative to the fossil-based plastics of bike helmet liners. An amazingly versatile substance, La Saponara’s lab has been researching possibilities to leverage mycelium as a low-carbon emission, low-toxicity, compostable alternative to non-degradable materials like polyurethane and acrylic.

Scaling up to a project as large and complex as wind turbine blades is a next-level move involving a highly collaborative group.

“The project is mushrooming,” La Saponara jokes. “Creating this design requires work from multiple disciplines.”

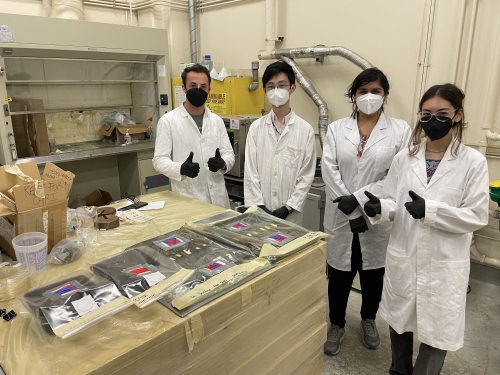

In addition to co-PI Barbato, who will support structural development, and research engineer Shuhao Wan, the project includes a diverse group of student researchers in engineering and design.

Bamboo and Waste Textiles

As luck would have it, La Saponara has a highly multidisciplinary researcher in her team, who is also a skilled bamboo artisan: Shuhao Wan, the lab’s instrumentation and design research engineer, has worked with bamboo as a hobby, crafting model ships in bottles. Wan is testing different ways to weave the bamboo reeds.

Meanwhile, the team is working on optimizing media for growing and attaching the mycelium layer. Mycelium is an amazing material because it can be grown where it’s going to be used – as long as the conditions are right. The fungal mass can thrive in waste streams from coffee grounds to discarded plastics, with its feedstock influencing its properties. But mycelium doesn’t eat everything, and naturally anti-fungal bamboo is not on the menu. The team is testing an ecologically friendly medium: post-consumer textile waste, which may offer the bonus outcome of growing the mycelium using waste otherwise bound for landfill.

Plans for Prototyping

The team plans to test a prototype this coming winter quarter. They will replace the blades on a commercial one-kilowatt turbine with the mycelium-bamboo composite and set up near the STEEL Lab, part of the Western Cooling Efficiency Center, away from central campus, to test the resilience of these blades.

These are early days toward the eventual goal of scaling the blades for global use. But La Saponara’s motivation is strong.

“What we’re doing right now doesn’t work anymore,” she said. “We’re at a tipping point in the environment, and our next generation are the ones who will pay the highest price. Ultimately, there’s no way we can talk about environmental engineering without talking about environmental justice.”

Meet the Team

Co-PI Michele Barbato will support structural development.

Shuhao Wan, the lab’s instrumentation and design research engineer, is investigating ways to build the blades, including structuring the bamboo layer.

Shree Nagarkar, a Ph.D. student in Mechanical and Aerospace Engineering, is investigating the aerodynamics and fluid-structure interaction behavior of these flexible wind turbine blades.

Alejandra Ruiz, Master of Fine Arts student in the Department of Design, is investigating mycelium growing on textiles. Ruiz is mentored by Christina Cogdell, Professor in the Department of Design and a biodesign expert.

Aidelen Montoya, CSU San Marcos in Museum Studies, Arts and History, a summer research undergraduate student who is studying mycelium growing from paper for various applications. Montoya is mentored by Lucy HG Solomon in CSUSM’s Department of Art, Media and Design.